SERVICES - PRODUCTIONS

Designed to Deliver End to End Solutions

Designed to Deliver End to End Solutions

Designed to Deliver End to End Solutions

Building on our proven expertise in core operational areas, Pavni is expanding upstream into Design and Procurement offering truly integrated project solutions. Our strength lies in a multi-skilled leadership team, a strong technical work ethic, and the ability to scale rapidly to meet evolving client needs.

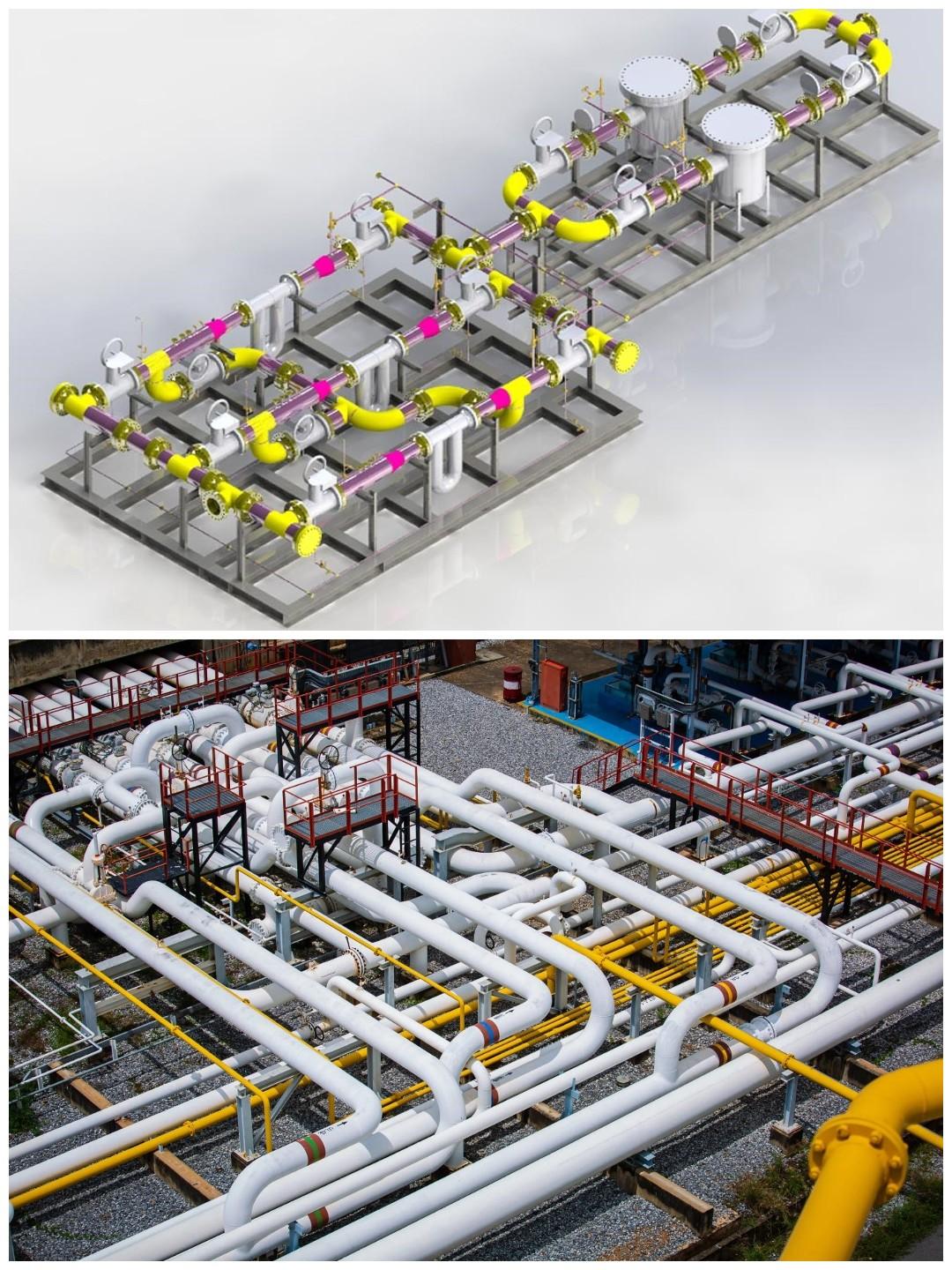

Our team is equipped with specialized skills in 3D Modeling, Structural Design & Load Analysis, Plant and Equipment Design, Piping Stress Analysis, SIL, P&ID, and CFD Analysis—catering to Thermal, Biogas, Petrochemical, and Chemical industries

We bring deep proficiency in industry-standard tools and platforms including: AutoCAD, STAAD Pro, RFEM, Inventor, AVEVA, Unigraphics, CATIA, Pro-E, SolidWorks, ACAD Plant 3D, PDS, PDMS, E3D, SP3D, HTRI, CAESAR II, PV Elite, Hyper Mesh, ANSYS, COSMOS, SPI, and more.